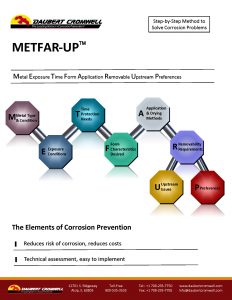

By answering this logical sequence of questions, you will be able to identify the right solution for your metals packaging application. It’s a simple formula, called METFAR-UP®

By answering this logical sequence of questions, you will be able to identify the right solution for your metals packaging application. It’s a simple formula, called METFAR-UP®

So how does VCI work?

Corrosion inhibitor compounds vaporize from the paper or film. They are attracted to the charged surface of the metal by virtue of their polar orientation. The VCI molecules align on the surface of the metal creating a layer of molecules on the charged metal surface. This barrier prevents oxidation.

When metals are wrapped or packaged in VCI, the chemicals volatilize in the packaging environment, forming a protective molecular layer on the surface of the metal.

Our VCI Education page explains how VCI works to protect your valuable metal parts and machinery during all stages of manufacture, export, storage, lay-up and preservation.

Have a corrosion problem? We can help you choose the right VCI to solve it. Just explain your situation in the form below.